Consultation service hotline

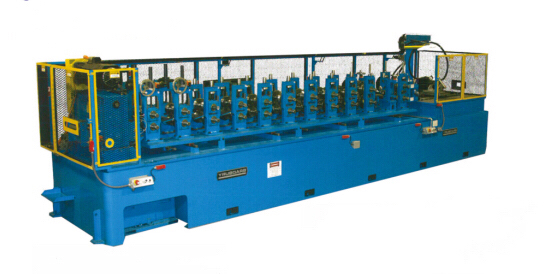

New cold bending machine takes you to light steel building material - light steel keelHeure publiée:2018-11-23 09:53 Light steel keel, is a new type of building materials, with the development of China's modernization construction, light steel keel is widely used in hotels, terminals, car transport stations, stations, amusement parks, shopping malls, factories, office buildings, old buildings building renovation, interior decoration Settings, roof and other places. Light steel (baking paint) keel ceiling has light weight, high strength, waterproof, shockproof, dustproof, sound insulation, sound absorption, constant temperature and other functions, but also has the advantages of short construction period, simple construction. Light steel keel is a high quality continuous hot galvanized sheet as raw material, after the cold bending process of rolling into the construction of metal skeleton. It is used to decorate the non-bearing wall and the roof of the building with paper plasterboard, decorative plasterboard and other light board. It is suitable for many kinds of building roof decoration, the inside and outside walls of the building and the basic materials of the pergola ceiling. Have condole top keel and partition keel by utility, have v-shaped, c-shaped, t-shaped, l-shaped keel by sectional form. This shows that the demand for light steel keel machine is also expanding, new cold bending machinery main ridge tile molding machine, railing plate molding machine, shelf molding machine, glazed tile pressure machine, floor bearing plate pressure machine, C/Z/U steel machine, C/Z exchange steel machine, C steel frame machine, light steel keel machine, sink machine and so on. Light steel keel has condole top keel and partition keel by use, have v-shaped, c-shaped, t-shaped, l-shaped, u-shaped keel by sectional form. (1) product specifications series partition keel main specifications are divided into Q50, Q75 and Q100. The main specifications of ceiling keel are D38, D45, D50 and D60. (2) product marking method: the marking order of light steel keel is: product name, code name, width, height of section shape, thickness of steel plate and standard number. If the section shape is "C" type, the width is 50mm, the height is 15mm, and the steel plate thickness is 1.5mm, the ceiling keel is marked as: light steel keel DC 50 XIS XI for construction. SGBllg sl (3) the appearance quality of light steel keel should be smooth with clear edges and corners, and no burr or deformation that may affect the use of the cut is allowed. Galvanized layer is not allowed to skin, tumor, fall off and other defects. For corrosion, damage, black spot, pitting and other defects, according to the specified method should be in accordance with the provisions of table 2-81. During appearance quality inspection, visual inspection should be carried out under the condition of bright light 0.5m away from the product. Light steel keel surface should be galvanized anti-rust, the amount of two-sided galvanized: no less than 120g/m*m, no less than 100g/m*m, no less than 80g/m*m qualified products. Special point V-type hanging keel, also known as card keel, national decoration materials patent number (main dragon -ZL002 63956.4; Vice dragon -ZL003 34437.1). All break the form of keel of traditional condole top in design manufacturing respect, use the snowflake board of high grade to make raw material, fire prevention, prevent rust, anti-ageing performance is strong, each function all passes a country to detect (gb11981-2001), construction is convenient, the effect is outstanding, apply extensively in contemporary adornment project. 1, when used in the ceiling, the long side of gypsum board must be vertical with the subkeel or laid in each city, fixed parts (from tapping screw) with the distance of gypsum board about 10-16mm, when fastening, gypsum board must be fixed with the skeleton; 2. When fixing the board, fix the board with the long and short sides in the middle of the board. 3, plasterboard butt should be tight, the seam must add horizontal keel, plasterboard should be installed in a state of no stress, not forced pressure positioning, should ensure that the bottom of the vice keel in the same plane, keel extension long insertion position should stagger. Installation method Play line Use level in the room (column) Angle on each wall take out point (if the wall is longer, the middle is also appropriate to copy a few points), pop-up level (level line according to the ground is usually 500 mm), from the standard line to condole carries on the design height plus 12 mm (the thickness of a layer of white bone plate), with a chalk line (column) along the wall popup level line, for suspended ceiling keel namely skin under line. At the same time, according to the ceiling plan, in the concrete roof pop-up main keel position. The main keel shall be divided from the center of the ceiling to both sides, with the maximum spacing of 1000mm, and mark the fixed points of the boom, with the spacing of the boom fixed points of 900mm ~ 1000mm. If the fixed point of the beam and pipe is larger than the design and procedure requirements, the fixed point of the boom should be added. Fix the hanging rod Use expansion bolts to fix the hanging rod. Not the top of the ceiling, the length of the boom is less than 1000mm, can be used with a boom of 6, if the big 1000mm, should be used with a boom of 8, also should set reverse support. The suspender may be cold-drawn and round bars, but round bars shall be mechanically straightened. The ceiling of the people, the length of the boom is less than 1000mm, can be used with 8 boom, if larger than 1000mm, should be used with 10 boom, also should set reverse support. One end of the boom should be welded with the L30×30×3 Angle code (the aperture of the Angle code should be determined according to the diameter of the boom and expansion bolt), and the other end can be used to tap out the screw rod larger than lOOmm, or the finished screw rod can be purchased for welding. The finished suspender should be rust-proof. The suspender should be fixed on the floor with expansion bolts and punched with electric hammer Hang the rod on the beam (1) the hanging rod shall be straight and have sufficient bearing capacity. When the embedded bars need to be extended, they must be welded firmly and fully. (2) the distance between the boom and the end of the main keel shall not exceed 300mm, otherwise, the boom shall be added (3) additional suspender shall be provided for ceiling lamps, tuyere and access port. V - type hanging keel installation Side keel Sub - keel keelson and dark keel two. Ceiling of condole of dark keel: when installing cover face plate namely second keel is enclosed in shed, cannot see in ceiling surface second keel. Ming long bone condole supports: when installing cover face plate namely second keel is exposed in cover face plate next, can see in ceiling surface second keel. The secondary keel should be mounted against the main keel. Subkeel spacing 300 ~ 600mm. Second keel cent is keel of keel of paint of T form bake, aluminium alloy keel of T shape, and all sorts of strip gusset plate manufacturer matchs the special keel that take. Join piece of iron of T form galvanize when fixing second keel on advocate keel, the two ends of second keel should be put on the horizontal flange of L form side keel, strip gusset plate has the line of shade Angle of special side keel to do. |